Metal Window Frame Kit 101: The Complete Guide

Those stunning, light-filled spaces with expansive glass walls and sleek, minimal frames don't happen by accident. The secret to achieving that clean, modern look lies in the strength of the structure holding the glass. Steel’s incredible rigidity allows for those barely-there profiles that maximize your view and flood a room with natural light. It all starts with the right foundation. A high-quality metal window frame kit is the essential first step in creating this aesthetic. It provides the robust support needed for large panes of glass, ensuring your window installation is not only beautiful but also secure and built to last for decades.

Key Takeaways

- Get a Professional Fit Without the Guesswork: A metal window frame kit is an all-in-one solution that provides the pre-cut steel and hardware for a sturdy installation. This system ensures your window is perfectly square, secure, and ready for a tight, weatherproof seal.

- Focus on Three Key Quality Markers: When choosing a kit, prioritize three things: a low steel gauge for strength (thicker is better), precise dimensions that match your opening, and a thermal break to prevent energy loss. These features guarantee long-term durability and performance.

- Master the Installation Details for a Leak-Proof Finish: A successful installation comes down to the details. Always use a level to ensure the frame is perfectly plumb, layer your flashing tape correctly to shed water, and use only low-expansion foam to insulate gaps without warping the frame.

What Is a Metal Window Frame Kit?

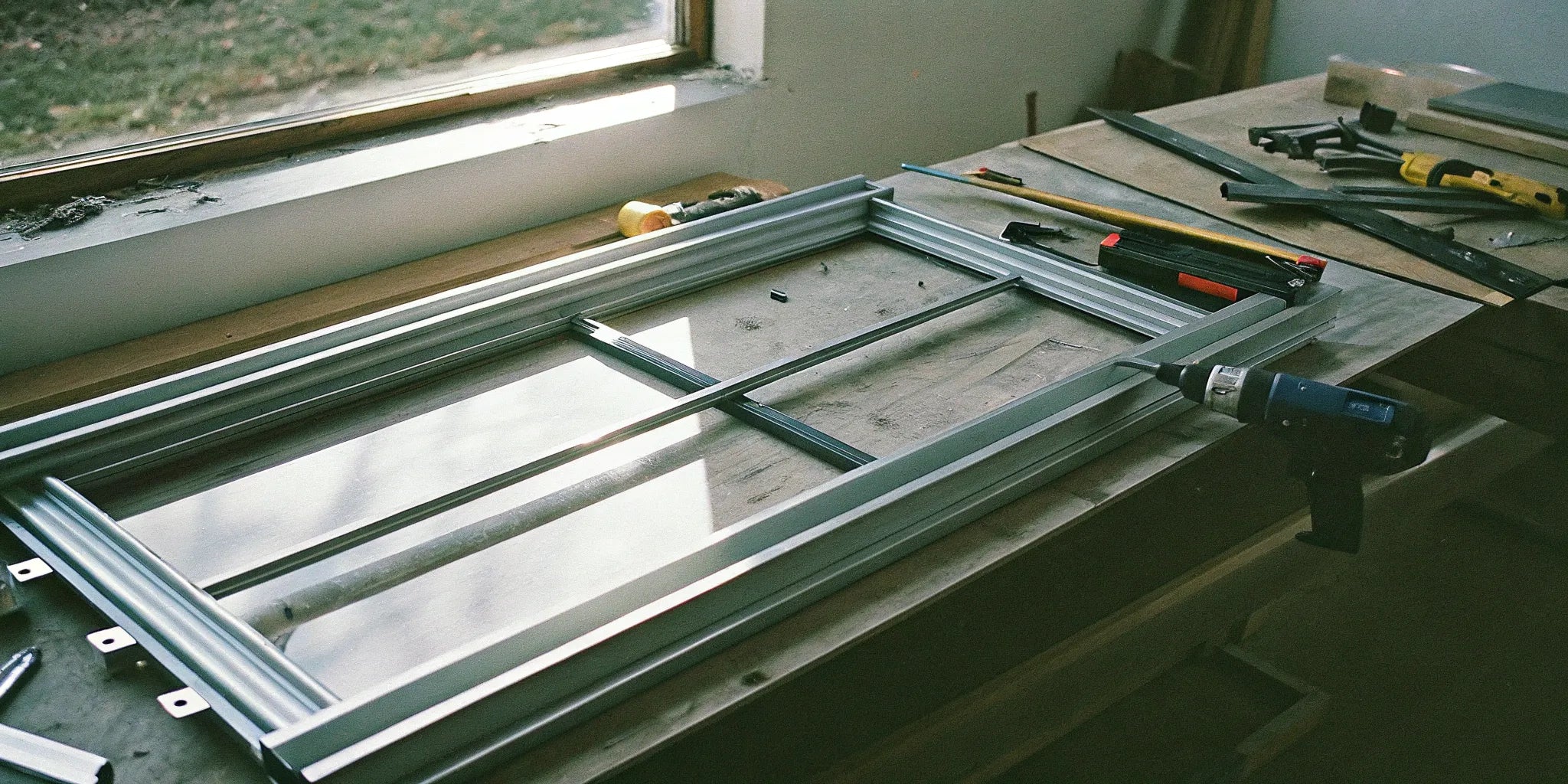

If you’ve ever felt overwhelmed by the thought of installing a window, a metal window frame kit is designed to make your life easier. Think of it as a complete, pre-packaged solution that provides the structural support needed to install a window into a wall opening. Instead of sourcing and cutting individual pieces of lumber or steel, these kits come with all the pre-measured and pre-drilled components you need to build a sturdy, perfectly square frame. This simplifies the process, reduces installation time, and helps ensure a professional result, whether you're a seasoned contractor or a confident DIYer.

These kits are especially useful in buildings with steel framing but are also commonly used in traditional wood-framed construction. The primary goal is to create a stable and secure housing for the window unit itself. By using a kit, you get a consistent, high-quality frame that’s ready for your new steel windows, ensuring a tight seal and flawless operation for years to come. It’s a straightforward approach that takes the guesswork out of one of the most critical steps in window installation.

Steel vs. Aluminum: Choosing the Right Material

When it comes to metal frames, steel and aluminum are the top contenders, and each brings something different to the table. Steel is the powerhouse choice, offering unmatched strength and security. Its rigidity allows for incredibly slim frames that can support large panes of glass, creating a sleek, modern look with maximum natural light. Because it’s so strong, it won’t warp or bend over time, making it ideal for large openings and areas with extreme weather.

Aluminum is a lighter, more cost-effective alternative that is naturally resistant to corrosion. It’s a durable material that holds up well in many environments, but it doesn’t quite match the sheer strength of steel. Your choice really comes down to your project's priorities. If top-tier security, longevity, and a minimalist aesthetic are your goals, steel is the clear winner.

What's Included in a Standard Kit?

Opening a metal window frame kit feels a bit like opening a grown-up LEGO set—everything you need for the structure is right there. A standard kit typically includes all the essential metal components, cut to size and ready for assembly. You can expect to find the head (top piece), sill (bottom piece), and jambs (side pieces) that form the rectangular frame.

Along with the main frame parts, the kit will contain the necessary hardware, such as brackets, fasteners, and screws, to put it all together securely. It’s important to remember that the kit is for the frame itself. The actual window unit, along with materials like flashing, insulation, and sealant, will need to be purchased separately to complete the installation.

The Top Benefits: Durability and Energy Efficiency

Two of the biggest advantages of choosing a metal window frame are its incredible durability and surprising energy efficiency. Metal, especially steel, is built to last. Unlike wood, it won’t rot, warp, or crack when exposed to moisture or fluctuating temperatures. This resilience means your windows will continue to open and close smoothly for decades with very little maintenance. This same strength is what makes steel doors a top choice for security, and that peace of mind extends to your windows, which serve as a formidable barrier against intruders and harsh weather.

You might not immediately associate metal with insulation, but modern engineering has completely changed the game. Many high-quality metal frames now include a "thermal break"—a strip of low-conductivity material that separates the interior and exterior metal surfaces. This simple addition dramatically reduces heat transfer, keeping your home warmer in the winter and cooler in the summer. This technology allows you to enjoy the strength and sleek look of metal without sacrificing your home's energy performance or comfort.

Common Myths About Metal Frames, Debunked

Metal window frames have been around for a long time, and so have a few persistent myths about them. It’s time to set the record straight. One of the most common misconceptions is that metal frames are poor insulators and will make your home drafty. While older, solid metal frames did have this issue, modern frames with thermal breaks are highly energy-efficient. They effectively stop temperature transfer, making them a smart choice for any climate.

Another myth is that all metal frames, particularly steel, are destined to rust. This couldn't be further from the truth for today's products. Quality steel frames are protected with advanced coatings, like galvanization or powder coating, which create a durable barrier against moisture and prevent corrosion. Finally, some people think metal windows only belong on commercial buildings. With their slim profiles and clean lines, modern metal frames are a favorite among architects for creating elegant, light-filled residential spaces that feel both timeless and contemporary.

How to Choose the Best Metal Window Frame Kit

Picking the right metal window frame kit is about more than just looks—it’s about ensuring a perfect fit, long-term durability, and a smooth installation. With so many options out there, it’s easy to feel overwhelmed. But by focusing on a few key details, you can confidently select a kit that meets your project's needs and stands the test of time. Think of it as a checklist for quality. Before you add anything to your cart, walk through these five critical points to make sure you’re getting the best possible frame for your home or commercial building. From the thickness of the steel to the quality of the screws, every element plays a role in the final result. Let’s break down exactly what you should be looking for.

Check the Material Gauge and Specifications

The first thing to look at is the thickness of the metal, also known as its gauge. For steel frames, a lower gauge number means thicker, stronger steel. This detail is a direct indicator of the frame's strength and ability to withstand impact and daily wear. For example, a quality kit might be "made from strong 2-inch by 3-inch steel, 15-gauge thick," which tells you it’s built for resilience. Always check the product specifications for this information. A robust frame not only supports the window properly but also contributes to the overall security of your property. When you’re investing in high-quality steel windows, pairing them with a sturdy frame is non-negotiable.

Ensure the Size and Dimensions Are Compatible

This might seem obvious, but it’s a step where mistakes can easily happen. Before you buy, double-check your measurements for the rough opening where the window will go. A good frame kit should offer some flexibility; for instance, some kits are designed to "work with both 2-inch by 3-inch and 2-inch by 4-inch building frames." This kind of versatility makes installation much simpler, especially in older homes where wall dimensions might not be standard. If your project has unique dimensions, look for suppliers that offer custom sizing. A frame that fits perfectly will be easier to install, look more professional, and perform better over time.

Inspect the Quality of Hardware and Components

A window frame kit is more than just the metal pieces; it’s a complete system. The quality of the smaller parts, like brackets and screws, is just as important as the frame itself. A reliable kit "comes with the 2-inch by 3-inch frame parts, brackets, and screws you need," ensuring you have all the necessary components for a secure assembly. Check that the included hardware is made from corrosion-resistant materials, like galvanized or stainless steel. This prevents rust and ensures your window remains securely in place for years. Having everything included in one package saves you time and guarantees that all the parts are designed to work together seamlessly.

Consider Frame Weight and Structural Needs

Metal frames are sturdy, but that strength comes with weight. It’s important to know how much the frame weighs to ensure your wall can handle the load. For example, if a "frame kit weighs 44.71 pounds," you need to add that to the weight of the window glass and any other components. This total weight must be supported by your wall’s structure, including the header, sill, and studs. For larger window installations or renovations in older buildings, it’s always a good idea to confirm that the existing structure is up to the task. If you have any doubts, consulting a contractor or structural engineer can prevent serious issues down the road.

Look for Thermal Breaks for Better Insulation

One of the biggest advancements in metal window frames is the thermal break. Metal is a natural conductor, meaning it can transfer heat and cold from the outside in. A thermal break is a piece of low-conductivity material placed between the interior and exterior parts of the frame to stop this transfer. While "it's certainly true that aluminum frames will produce condensation faster because they're metal," frames with thermal breaks solve this problem. This feature dramatically improves a window's insulating properties, helping to keep your home comfortable and your energy bills down. When choosing a kit, especially for exterior steel doors and windows, a thermal break is a must-have for modern energy efficiency.

How to Install a Metal Window Frame Kit

Installing a metal window frame might seem like a job reserved for seasoned contractors, but with careful planning and the right instructions, it’s a project that a skilled DIYer can confidently tackle. A proper installation is key to getting the most out of your investment, ensuring your windows not only look fantastic but also provide top-notch security, durability, and energy efficiency for years to come. The clean lines and robust nature of steel windows can completely transform a space, adding a touch of modern elegance or industrial chic.

This guide will walk you through the essential steps, from gathering your supplies to adding the final touches. We’ll break down the process into manageable stages, share some professional tips, and help you avoid common pitfalls. Whether you’re replacing an old unit or framing a brand-new opening, understanding the fundamentals will help you achieve a secure, level, and weather-tight installation that you can be proud of. Let’s get started.

Gather Your Tools and Materials

Before you begin, lay out all your tools and materials to ensure a smooth workflow. Having everything within arm’s reach prevents interruptions and helps you stay focused. While your specific kit will include the window frame and hardware, you’ll need to supply the rest.

Materials:

- Shims (wood or composite) for leveling

- High-quality exterior caulk or sealant

- Self-adhering flashing tape

- Low-expansion spray foam insulation

- Screws or fasteners appropriate for your wall type

Tools:

- Power drill/driver with bits

- Level (a 4-foot level is ideal)

- Measuring tape

- Utility knife

- Caulking gun

- Safety glasses and gloves

A Step-by-Step Guide to Installation

While you should always follow the manufacturer’s specific instructions, most metal window frame installations follow these general steps. Precision is your best friend here—measure twice, and then measure again.

- Prepare the Rough Opening: Make sure the opening is clean, structurally sound, and sized correctly for your window frame. The surface should be smooth and free of debris.

- Apply Flashing: Begin applying self-adhering flashing tape to the sill and up the sides of the opening. This creates your first line of defense against water intrusion.

- Set the Frame: Apply a bead of sealant along the interior edge of the window’s mounting flange. Carefully lift the frame into the opening, pressing it firmly against the wall sheathing.

- Level and Shim: Use shims to ensure the frame is perfectly level and plumb. Check all four corners before securing it.

- Fasten the Frame: Secure the frame to the wall using the recommended fasteners, being careful not to overtighten and warp the frame.

- Seal and Insulate: Apply flashing over the side and top flanges. From the inside, fill any gaps between the frame and the rough opening with low-expansion foam.

Pro Tips for a Flawless Finish

The secret to a leak-proof window isn’t just sealant—it’s a properly layered flashing system. Think of it like shingles on a roof, where each piece overlaps the one below it to direct water away from the opening. A great guide to window flashing can show you the best techniques for creating a durable water barrier.

One of the most important pro tips is to never seal the bottom flange of the window to the exterior wall. This might feel counterintuitive, but leaving it unsealed creates a path for any water that might find its way behind the side flanges to escape. Sealing it can trap moisture, leading to rot and water damage inside your walls.

Common Mistakes to Avoid

Even small errors during installation can lead to big problems like drafts, leaks, or difficulty operating the window. In fact, some experts estimate that the vast majority of window leaks are due to installer error, not a faulty product.

Here are a few common mistakes to watch out for:

- Forgetting to Level: An unlevel frame will cause the window sash to stick or swing open on its own. Use your level constantly throughout the process.

- Over-tightening Fasteners: Driving screws in too tightly can distort or bow the metal frame, making the window difficult to open and close.

- Using the Wrong Insulation: High-expansion foam can exert enough pressure to warp the frame. Always use a low-expansion foam specifically designed for windows and doors.

DIY vs. Hiring a Professional: Which Is for You?

Deciding whether to install your window frame yourself or hire a professional comes down to your skill level, the tools you have, and the complexity of your project. If you’re an experienced DIYer replacing a single, easily accessible window, you can likely handle the job with great results.

However, if you’re working with a large custom unit, a new construction project, or an opening that requires structural changes, hiring a professional is a wise investment. A pro has the experience to troubleshoot unexpected issues and can guarantee their work. For contractors and builders, joining a trade program can provide access to bulk pricing and specialized support for projects of any scale.

Finding the Right Size and Style for Your Project

Once you know what to look for in a quality kit, the next step is matching it to your specific project. The perfect window isn't just about the frame material; it's about how it fits into your building's structure, purpose, and overall design. Whether you're renovating a historic home or constructing a modern commercial space, getting the size and style right is key to a successful installation. Let's walk through the main considerations to ensure your new windows look great and perform flawlessly for years to come.

Residential vs. Commercial Frame Requirements

While both homes and businesses benefit from durable windows, their specific needs can differ. For residential projects, aesthetics and security are often top priorities. Homeowners love that steel-framed windows offer superior strength and slim profiles, creating a secure and stylish look with expansive views. Energy efficiency is also a major factor in keeping utility bills down and maintaining a comfortable living space.

Commercial buildings, on the other hand, usually face stricter building codes and structural demands. These projects may require larger window units, higher wind-load ratings, and specific safety features. The inherent strength of steel makes it an ideal choice for these applications, as it can support vast panes of glass and withstand the rigors of a high-traffic environment, ensuring long-term durability and performance.

Understanding Frame Depth and Profile Options

Getting into the technical details, frame depth and profile are two terms you'll want to know. Frame depth refers to the thickness of the window frame from the interior to the exterior. It’s crucial that this measurement is compatible with your wall’s thickness to ensure a proper, weather-tight fit.

The profile is the shape and width of the frame material you see. Steel’s incredible strength allows for very slim, minimalist profiles, which maximize your glass area and create a clean, modern aesthetic. These sleek frames are not only stylish but also incredibly durable. When properly coated, the metal resists corrosion, making it a reliable choice even in coastal or high-wind areas where weather resistance is essential.

Custom vs. Standard Sizing

One of the biggest decisions you'll make is whether to go with standard or custom-sized windows. Standard sizes are mass-produced to fit common rough openings, which often makes them more affordable and quicker to ship. If your project uses conventional dimensions, choosing from a range of standard steel doors and windows can be a practical and budget-friendly option.

However, many projects have unique requirements. For historic renovations, architecturally distinct homes, or large-scale designs, custom sizing is the way to go. Custom windows are built to your exact specifications, giving you complete creative freedom over the size, shape, and configuration. This ensures a perfect fit for any non-standard opening and allows you to achieve a truly bespoke look.

Ensuring Compatibility with Your Wall Type

Finally, your window frame kit must be compatible with your wall construction. Whether you’re working with traditional wood studs, masonry, or a steel-frame building, the installation method and anchoring requirements will vary. Adding windows to any structure is completely doable, but it requires careful planning to maintain structural integrity and prevent issues like water leaks.

Before you order, identify your wall type and thickness. This information will help you select the right frame depth and ensure you have the correct flashing and fasteners for the job. For example, installing a window in a wall finished with fiber cement boards will have different considerations than installing one in a brick facade. A little prep work here ensures a smooth installation process.

Where to Buy Your Kit and What to Expect

Once you’ve figured out the right size, style, and material for your project, it’s time to find a supplier. This step is just as important as choosing the kit itself, as a good partner can ensure you get a high-quality product, fair pricing, and the support you need. Knowing what to expect in terms of cost, warranties, and long-term care will help you make a confident and informed purchase. Let’s walk through the key things to consider when you’re ready to buy.

What Factors Influence the Price?

The final price tag on your metal window frame kit depends on a few key factors. Size is the most obvious one—larger or custom-sized frames will naturally cost more than standard dimensions. The quality and thickness of the metal also play a significant role, as does the type of finish. A basic powder coat will be more budget-friendly than a premium, textured finish designed to withstand harsh weather. Finally, any special features, like integrated thermal breaks for improved insulation or complex designs, will add to the cost. While it can be tempting to go for the lowest price, remember that durable, high-quality steel windows offer better long-term value by reducing energy and maintenance costs down the road.

Ask About Trade and Bulk Discounts

If you’re a contractor, builder, or a homeowner tackling a large-scale renovation, don’t leave money on the table. Many suppliers offer special pricing for trade professionals or discounts on bulk orders. It never hurts to ask your supplier if they have a program you can join. At USA Builders Depot, we offer a trade application to give professionals access to exclusive pricing and support. This is a simple way to manage your project budget effectively while still getting access to premium materials. Planning ahead and consolidating your purchase can often lead to significant savings, so be sure to inquire about your options before placing an order.

Understanding Warranty and Quality Assurance

A good warranty is more than just a piece of paper; it’s a manufacturer’s promise that their product is built to last. Before you buy, always check the warranty details for any window frame kit you’re considering. Look for comprehensive coverage that protects against structural defects in the frame as well as issues with the finish, like chipping or fading. A strong warranty, often lasting 10 to 20 years, shows that the company stands behind its craftsmanship. Reading customer reviews can also give you insight into a company’s commitment to quality and service, helping you feel confident that you’re investing in a product that will perform well for years to come.

Maintenance Tips for Long-Lasting Windows

One of the biggest perks of choosing modern metal window frames is how little maintenance they require. Unlike wood, high-quality steel and aluminum frames won’t warp, rot, or need repainting every few years. Because the metal is so strong and durable, it holds up exceptionally well in all kinds of weather, from high winds to coastal air. To keep your frames looking their best, simply wipe them down with mild soap and water a few times a year to remove dirt and grime. It’s also a good idea to periodically check that the weatherstripping is intact and that any drainage holes are clear of debris. That’s it—a few minutes of care ensures your steel doors and windows will remain beautiful and functional for decades.